Jominy End Quench temperature profiling using thermal imaging

Description

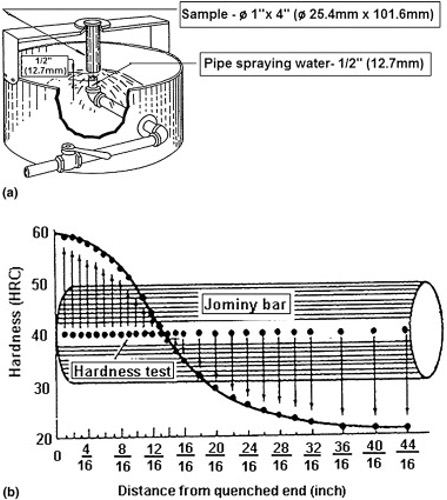

A Jominy end quench is a heat treatment procedure employed in metallurgy to assess the hardenability of a metal. It involves heating a cylindrical metal specimen uniformly and then rapidly quenching one end by directing a jet of water onto it, while the other end remains unaffected. The quenched end undergoes rapid cooling, inducing a martensitic microstructure, while the non-quenched portion experiences a slower cooling rate. By evaluating the resulting hardness profile along the longitudinal axis of the specimen, metallurgists can determine the metal’s ability to be hardened under different cooling conditions. This information is crucial for optimizing heat treatment processes and tailoring the material’s mechanical properties, such as strength and toughness.

This project aims to develop the instrumentation systems required to begin investigating the effects of cooling rate on hardenability. It is expected that this will be done via thermal imaging of the specimen during the cooling phase although other technologies may be investigated.

Key skills/interests:

Python programming, image processing, electronics design, materials science.

Expected outputs:

1x MSc (Eng), 1x Journal/Conference paper in a leading publication.

Supervisors:

James Hepworth and Sarah George